Metallic Threads add a zing and sparkle to your embroidery but they are notoriously difficult to use. The good news is that they can be tamed by understanding why they behave the way they do and by following these guidelines that will help prevent thread breakages.

There are many different types of metallic thread but most are basically a core fibre covered with a coating of metallic foil. For example, the Marathon threads 3004 to 3007 have a rayon core covered with polyester film that is metallised with silver.

This metallic coating means that metallic threads are not soft and supple like rayon threads – they are stiffer and do not drape as well. This is what makes them more of a challenge to use as when the thread unwinds from the reel, it can ‘kink’ and twist around itself. When this loop meets a thread guide, the resulting tension problem can cause the thread to break.

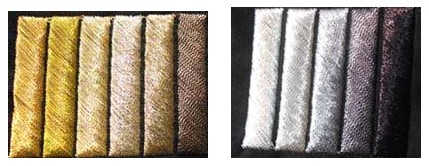

Here is a series of stitch outs using metallic and rayon threads to show how the look of the designs vary according to the type of thread used.

1. Embroidered in all metallic thread.

2. Embroidered in rayon and metallic threads.

3. Embroidered in an ‘old gold’ colour in rayon to give the appearance of metallic thread without the extra work involved. Marathon thread 1187.

Metallic threads come in many wonderful colours so experiment beyond the gold and silver.

And experiment with the different golds and silvers.

Sew a sample – it is always worth the time and effort

Always stitch a sample piece first using the same materials you’ll be using for your embroidery. Experiment with top tension, stabilizer, sewing speed, and needle and with ways of minimising kinking.

Follow these guidelines to tame your thread and to reduce thread breaks.

4. Loosen the top tension on your machine. Metallic thread is generally thicker than the 40–weight that your machine has been optimized for and certainly not as flexible. Each machine is different so experiment to find the best setting for you. I reduce my top tension by 50% or more, depending on the fabric and the density of the design.

5. Slow down the machine. This reduces the amount of tension on the thread and how much it stretches – then breaks. Again, experiment with different speeds when you do your sample piece. Start with a slow speed and, if you’re not having problems, increase it a little. Repeat this until the thread breaks and you’ll know what is too fast for your machine, with this design on this fabric. I prefer to slow right down (20% - 40% of maximum speed) and take more time embroidering and less time dealing with thread breaks.

6. Choose the right design – not all designs can, or should, be embroidered with metallic thread. Dense designs can result in the thread nesting underneath and consequent thread breaks. This butterfly design was embroidered in metallic threads with a rayon thread for the outline of the body. The design at the centre is very dense and caused nesting on the back.

Also avoid designs that have a lot of small stitches and overlapping sections. Remember, you can be selective and use metallic thread to only embroider a specific part of the design – enough to add the zing and highlight.

7. Choose a lightweight bobbin thread. A 60-weight bobbin thread (such as the Marathon bobbin thread and pre-wound bobbins) is ideal. I have heard of people using metallic thread in the bobbin but I have not tried this myself. When the back of the embroidered piece will be seen, I use a rayon thread (in a similar colour to the metallic thread) in the bobbin.

8. Use the right stabilizer. Metallic thread usually works better with a stabilizer that has a viscose or cotton component in them. Stabilizers with 100% can be too sturdy and create too much friction with needle and thread and increase the chance of thread breaks. Avoid thick and abrasive stabilizers and iron on stabilizers - the adhesive can build up on the needle and thread and the drag increases the friction.

9. Use the right fabric. A medium weight natural fabric (like cotton) is best suited to embroidery with metallic threads. Tightly woven, stiff and thick materials do not work as they increase unwanted friction while fine fabrics (like organza) are extremely difficult to use but can be worth the effort. Metallic thread can even be used on light cardboard and card stock if the design is not dense.

10. Freeze the thread for a few minutes before you use it. I have not tried it but if you’re still having problems after trying all the above suggestions – give it a go!

Written by Elaine Raahauge - business writer and home embroiderer

If you have a tip we have not included here or you have a question we can answer, please send us an email at sales@marathonaustralia.com.au, we will do our best to answer the question.