We embroiderers want to embroider beautiful designs on just about everything and today we have the machines that allow us to do just this. Each type of material poses its own problems with hooping and stabilisers and it can be really difficult knowing the best way to embroider on velvet, t-shirts, towels and suede – to name a few.

The good news is that somebody has gone to a lot of work to determine the best way to do all this and he has put all the information on his website for us to use. His name is Kenny from Embroidery Library and in his tutorials he covers just about everything from puckering and tension to choosing colours and embroidering in the hoop.

So, if you have ever wanted to embroider on fleece, spandex, sweaters, nylon, silk, faux fur, denim, tulle and even leather, go to emblibrary.com for detailed instructions.

Used with the kind permission of Embroidery Library.

There are so many types of stabilizers on the market today that it can be a problem figuring out what you need for your machine embroidery. This article covers the major types of stabilizers available and what materials they work best with. It gives you tips for working with difficult to hoop materials and some hints on hooping.

The major stabilizer categories covered here are:

There are many companies making stabilizers and their products have different names. For example, a water-soluble stabilizer made by Sulky is called Solvy while Floriani call theirs Wet N Gone. Marathon just calls theirs water-soluble stabilizer. Very confusing! Ultimately, most of the hundreds of stabilizer on the market can be grouped into these four categories and they will cover almost all your stabilizer needs.

Stabilizers come in different ‘weights’, e.g. light, medium and heavy and you select the weight that is right for your project. Tear-away and cut-away stabilizers often come in both black and white so you can match the colour to the material in your project. Most excess stabilizer is removed after the embroidery is completed and it is how it is removed that determines which category the stabilizer belongs to. So a tear-away stabilizer can tear in two or more directions and the excess is simply torn away after embroidering. The bit under the embroidery remains and adds more stability to the piece during use.

You must use a stabilizer when machine embroidering as it supports the fabric during the embroidery process and stops it slipping and distorting. You cannot produce a well-embroidered piece without using stabilizer.

And it is important to match the correct stabilizer to the fabric and to the design. If you are using a cotton material with a medium dense design, try using two layers of a lightweight tear-away. Some embroiderers prefer to use one layer of a medium to heavyweight tear-away stabilizer instead. There is no right answer – only guidelines - and you will need to experiment with a test piece for each new project.

1. Choose the right type of stabilizer for the fabric. Generally:

· Tearaways are used for woven fabrics such as cotton and denim as woven fabrics are more stable and don’t move as much in the hoop. Some tear-away stabilizers have an adhesive on side that is fused (ironed on) to the back of the fabric.

· Cutaways are used for stretch and knit (non-woven) fabrics as these are unstable fabrics and need the extra stability of a cutaway – which is more resistant to needle penetrations.

· Washaways are used whenever you want to remove the stabilizer completely after the piece is embroidered, e.g. free standing lace - but the fabric must be washable. Also used for toppings on napped materials.

· Topping film is used on top of material that has a high pile, e.g. towels, velvet, fleece and some knits. If you don’t use a topping, the stitches sink into the material and bits will poke out through the embroidery stitches. These are called ‘pokies’ and are to be avoided.

2. Choose the right weight of stabilizer for the fabric. Now we’re at the difficult part as there are no rules for this complex issue. You don’t just match a heavy weight stabilizer with a heavy weight material and the same for lightweight materials. Nor does it work by putting opposites together, e.g. putting a lightweight stabilizer with heavy material. Every combination of stabilizer and material has its own unique requirements. Take organza as an example. This is a very lightweight material that doesn’t stretch so it is stable. A heavyweight stabilizer would not work on such a lightweight fabric so a lightweight stabilizer would be the best choice. The fabric is also slippery and I would choose a lightweight stabilizer that provided the best protection against slippage – a fusible would be good. I would start with one layer of lightweight stabilizer and if there was any slippage, I would add another layer.

Fabrics that have a little or a lot of stretch are less stable than non-stretch fabrics so they need greater stabilization and possibly a heavier weight stabilizer or a fusible stabilizer.

The weight of the stabilizer ultimately comes down to stability and you need to work out what combination of stabilizer and material provides the best stability for the density of the design (see below). This is why you must do a test piece – even several test pieces to get it right.

3. Match the stabilizer to the design. The denser the design, the more stability has to be provided by a stabilizer to prevent distortion and puckering. A redwork design is usually low density (not many stitches in a given area) so does not need to be stabilized as much as a dense design that has multiple layers of thread in all or part of the design or a lot of fill stitches in a given area. Each time the needle penetrates the fabric and stabilizer, it leaves a hole. So the denser the design, the more needle penetrations there will be. Cut-away stabilizers are less resistant to needle penetrations than tear-aways (which is why cut-aways have to be cut and not torn away) and provide more stability during the embroidery process and afterwards, during normal wear and tear.

Free-standing lace is usually very dense so two or three layers of water soluble stabilizer are required to minimise distortion.

4. Use the least amount of stabilizer as possible. Start your test piece with one layer and, if there is puckering or the design is all over the place (outlines and registration marks don’t line up), add another layer. The thicker the stabilizer, the bulkier the finished piece will be.

5. Hoop the stabilizer properly. The stabilizer should be completely hooped with the material and have a minimum 2 cm border outside the hoop to keep the embroidery stable. Having said that, if I’ve started embroidering and I don’t feel that I’m using enough stabilizer, I’ll slip an extra layer between the hoop and the machine.

6. Use adhesive stabilizers with care. Tear-away stabilizers with fusible backings that are ironed on to the back of the material are often used to prevent the material and stabilizer separating (however slightly) during the embroidery process. Again, there is no wrong or right answer – some people swear by them other people won’t let gums and adhesives near their machine. See Hoopless Embroidery for Difficult Items and Materials, below.

If you like the idea of adhering the fabric and stabilizer together but don’t have a fusible stabilizer, you can use a spray adhesive – this is particularly useful when you want to adhere a cut-away stabilizer to the fabric. This adhesive must be made especially for material and NEVER spray it near the machine.

The embroidery is finished and it is time to remove the stabilizer. How you do it depends on the type of stabilizer used.

Tear-away stabilizer

Hold the embroidered section with one hand and tear the paper away from the embroidery – never into the embroidery as this will weaken the edges and may damage the design. If I don’t need to remove the stabilizer from the hard-to-access places, then I leave it there. It will provide support for the item during normal wear and tear. If it all has to come out, I carefully use small curved-tipped scissors and tweezers.

Cut-away stabilizer

This stabilizer has to be cut away and cannot be torn. Use the small curved-tip scissors to cut around the design. I put my finger between the stabilizer and the material and run the scissors along my finger to avoid cutting the material. Leave a small margin, if possible, to protect the edge of the design.

Water-soluble stabilizer

There is a tendency for the residue from water-soluble stabiliser to remain in the embroidered piece making the piece stiff and inflexible. This may be what you want if you are making a doily or lace segments for a bowl and you need the rigidity. Otherwise, you need to rinse as much of the stabilizer away as possible.

How to rinse out water-soluble stabilizer:

Silk, velvet, leather, suede and corduroy are just some material that shouldn’t be hooped –the pressure of the hoop causes a hoop ‘burn’ that cannot be removed so these materials are embroidered using the hoopless embroidery technique. This means that only the stabilizer is hooped and the material is stuck to the stabilizer using double-sided tape or spray on adhesive.

How to use double-sided tape for hoopless embroidery:

How to use spray on adhesive for hoopless embroidery:

Use either of these two methods to embroider towels and items that can’t fit into a hoop, e.g. the edge of a napkin and collars.

These are only suggestions and you must test your own combination.

But you don’t have to stick to these guidelines and I often use a cutaway on cotton material when I’m embroidering a dense design. The frequency and type of use also impacts on a garment, e.g. I would use a cut-away for a cotton garment that will receive a lot of machine washing as it will provide more protection against wear and tear.

You will not get a good result if you do not hoop the stabilizer and fabric properly. The material and stabilizer must be smooth and wrinkle free and must not be loose. Any loose material will be taken up by the embroidery and will result in puckering and distortion.

Most embroidery hoops have an inner and outer hoop with a tightening device such as a screw. The material is sandwiched between the inner and outer hoops.

The tension in a tightened hoop is not evenly distributed and will be looser at the screw area. Therefore, it is necessary to tighten the screw then remove the inner hoop to distribute the tension and re-hoop.

How to hoop material:

Never stretch the fabric once it has been hooped. It will just relax back into place after you remove the hoop and will result in puckering.

Hooping knits and other stretchy items can be difficult so you may want to use a fusible stabilizer or a spray adhesive first.

And lastly - only ever carry your hooped fabric by holding the hoop itself, otherwise you will stretch the fabric.

Here are other great tips from Embroidery Library.

Metallic Threads add a zing and sparkle to your embroidery but they are notoriously difficult to use. The good news is that they can be tamed by understanding why they behave the way they do and by following these guidelines that will help prevent thread breakages.

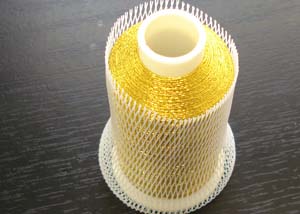

There are many different types of metallic thread but most are basically a core fibre covered with a coating of metallic foil. For example, the Marathon threads 3004 to 3007 have a rayon core covered with polyester film that is metallised with silver.

This metallic coating means that metallic threads are not soft and supple like rayon threads – they are stiffer and do not drape as well. This is what makes them more of a challenge to use as when the thread unwinds from the reel, it can ‘kink’ and twist around itself. When this loop meets a thread guide, the resulting tension problem can cause the thread to break.

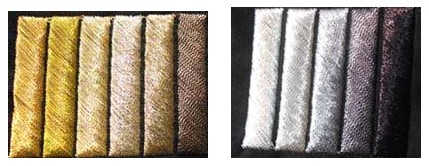

Here is a series of stitch outs using metallic and rayon threads to show how the look of the designs vary according to the type of thread used.

1. Embroidered in all metallic thread.

2. Embroidered in rayon and metallic threads.

3. Embroidered in an ‘old gold’ colour in rayon to give the appearance of metallic thread without the extra work involved. Marathon thread 1187.

Metallic threads come in many wonderful colours so experiment beyond the gold and silver.

And experiment with the different golds and silvers.

Sew a sample – it is always worth the time and effort

Always stitch a sample piece first using the same materials you’ll be using for your embroidery. Experiment with top tension, stabilizer, sewing speed, and needle and with ways of minimising kinking.

Follow these guidelines to tame your thread and to reduce thread breaks.

4. Loosen the top tension on your machine. Metallic thread is generally thicker than the 40–weight that your machine has been optimized for and certainly not as flexible. Each machine is different so experiment to find the best setting for you. I reduce my top tension by 50% or more, depending on the fabric and the density of the design.

5. Slow down the machine. This reduces the amount of tension on the thread and how much it stretches – then breaks. Again, experiment with different speeds when you do your sample piece. Start with a slow speed and, if you’re not having problems, increase it a little. Repeat this until the thread breaks and you’ll know what is too fast for your machine, with this design on this fabric. I prefer to slow right down (20% - 40% of maximum speed) and take more time embroidering and less time dealing with thread breaks.

6. Choose the right design – not all designs can, or should, be embroidered with metallic thread. Dense designs can result in the thread nesting underneath and consequent thread breaks. This butterfly design was embroidered in metallic threads with a rayon thread for the outline of the body. The design at the centre is very dense and caused nesting on the back.

Also avoid designs that have a lot of small stitches and overlapping sections. Remember, you can be selective and use metallic thread to only embroider a specific part of the design – enough to add the zing and highlight.

7. Choose a lightweight bobbin thread. A 60-weight bobbin thread (such as the Marathon bobbin thread and pre-wound bobbins) is ideal. I have heard of people using metallic thread in the bobbin but I have not tried this myself. When the back of the embroidered piece will be seen, I use a rayon thread (in a similar colour to the metallic thread) in the bobbin.

8. Use the right stabilizer. Metallic thread usually works better with a stabilizer that has a viscose or cotton component in them. Stabilizers with 100% can be too sturdy and create too much friction with needle and thread and increase the chance of thread breaks. Avoid thick and abrasive stabilizers and iron on stabilizers - the adhesive can build up on the needle and thread and the drag increases the friction.

9. Use the right fabric. A medium weight natural fabric (like cotton) is best suited to embroidery with metallic threads. Tightly woven, stiff and thick materials do not work as they increase unwanted friction while fine fabrics (like organza) are extremely difficult to use but can be worth the effort. Metallic thread can even be used on light cardboard and card stock if the design is not dense.

10. Freeze the thread for a few minutes before you use it. I have not tried it but if you’re still having problems after trying all the above suggestions – give it a go!

Written by Elaine Raahauge - business writer and home embroiderer

If you have a tip we have not included here or you have a question we can answer, please send us an email at sales@marathonaustralia.com.au, we will do our best to answer the question.

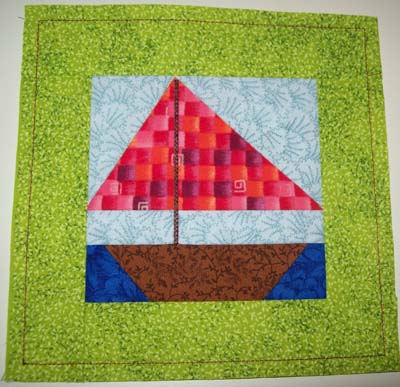

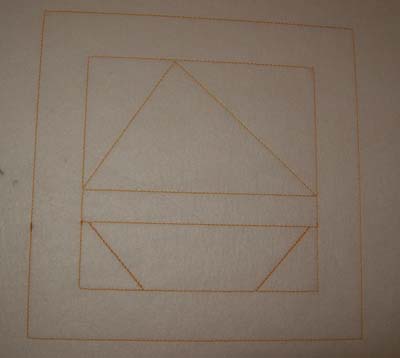

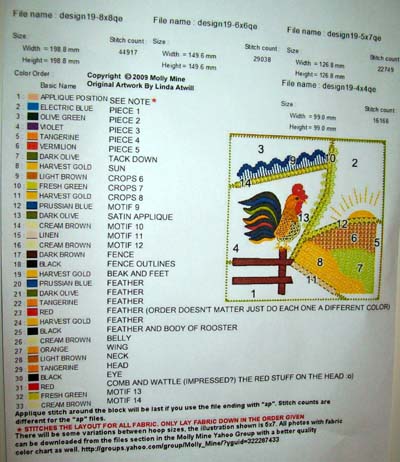

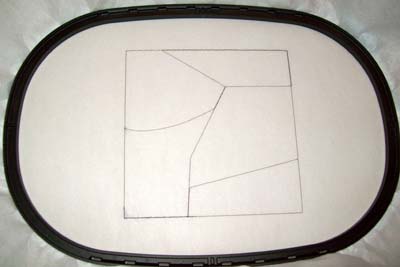

Embroidery machines today do much more than embroider and there are creative digitizers out there who are finding new ways for us to use our embroidery machines – including creating a patchwork block in your embroidery hoop by a method called piecing in the hoop. This is similar to foundation piecing but, as all the stitches are programmed into the embroidery design, the completed block is much more accurate.

This tutorial covers some of the basics of piecing in the hoop but each designer creates their designs differently so you cannot religiously follow the steps detailed here for all designs. I have written this tutorial to show you what is possible with your embroidery machine and to encourage you to create beautiful and fun things.

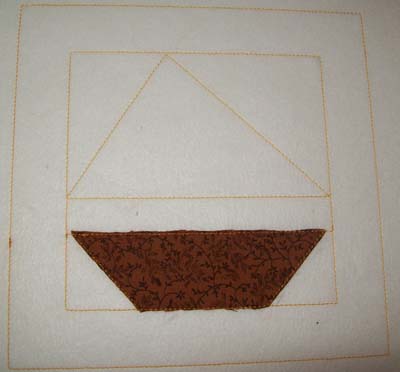

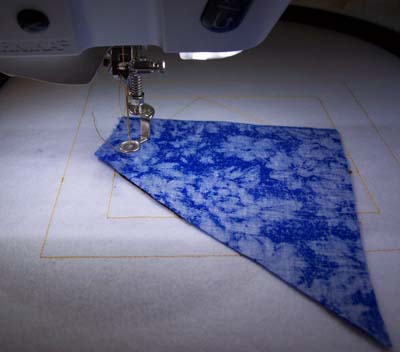

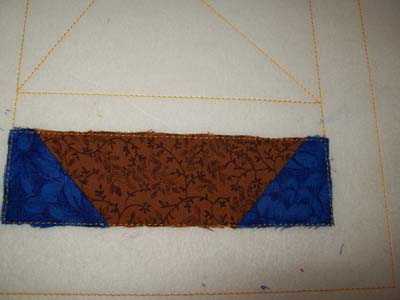

Follow these instructions to create this fun quilt block entirely in the embroidery hoop.

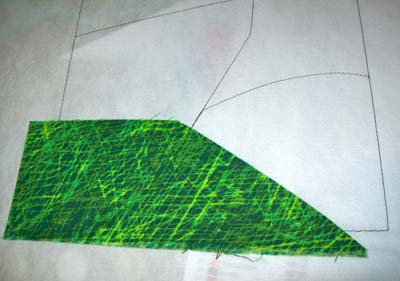

If you have ever tried paper or foundation piecing then you’ll know that you can create patchwork blocks by layering pieces of material one over the other, in sequence, and stitching them down. Well, this is the same except each seam is considered a piece of embroidery and the whole block is created in the hoop.

There are six things you need to create a patchwork block similar to the boat block demonstrated here:

There are a lot of thread colours at the beginning of the block but it is not necessary to change the actual thread. They are called thread stops and are put there by the designer to stop the machine so you can place, or trim, the patchwork piece of material. Therefore, it is not necessary to change your thread each time there is a thread stop as this thread will not be seen. In the steps for Creating the patchwork block (below), it is not necessary to change the thread colour until step 11.

Trim the finished block and remove the stabilizer, if required.

Written by Elaine Raahauge - business writer and home embroiderer

You can make beautiful free standing lace (FSL) using your embroidery machine. This is lace that is meant to stand alone and is not embroidered onto other material (except possibly organza – more about that later).

The sample squares I made for this tutorial can be joined together to make a doily or even a tablecloth. You can make FSL to put on the edge of sheets or a tablecloth (why not make a tablecloth with cutwork corners and a lace trim). Other uses include Christmas ornaments, bookmarks, lace bowls or you can appliqué the lace to clothing. You can make beautiful 3D items, such as a flower or butterfly, by hooping a layer of netting or organza with the water-soluble stabilizer.

These items show what can be made using the FSL technique. These designs are digitized by Stanislava Krachunova of S-Embroidery and these samples are shown with the kind permission of the designer.

There are only four items you need to make FSL:

Join the finished pieces of FSL (on the wrong side) by butting them together and using invisible thread and a zigzag stitch on your sewing machine. You can also use the same colour rayon thread to join the pieces.

Go to s-embroidery.com for more tutorials on FSL including how to attach the lace to material to make this beautiful table runner. There are free designs that you can download – including a FSL Christmas stocking.

Written by Elaine Raahauge - business writer and home embroiderer

Silk, velvet, leather, suede and corduroy are just some material that shouldn’t be hooped –the pressure of the hoop causes a hoop ‘burn’ that cannot be removed so these materials are embroidered using the hoopless embroidery technique. This means that only the stabilizer is hooped and the material is stuck to the stabilizer using double-sided tape or spray on adhesive.

Use either of these two methods to embroider towels and items that can’t fit into a hoop, e.g. the edge of a napkin and collars.

Cutwork is making a comeback in fashion but few people have the time or the skills to create a beautiful cutwork tablecloth or blouse by hand. Fortunately, it doesn’t matter, as your embroidery machine will give you perfect results in a fraction of the time.

Follow the instructions in this tutorial to create this lovely cutwork design entirely in the embroidery hoop.

This is a technique where you cut out specific areas of your material and your machine embroiders (usually a satin stitch) around the cut edges to seal them. These cut out areas are usually connected by Richelieu bars, or bridges, which help the piece keep its shape after the stabilizer is removed.

The supplies you need will depend on whether or not the material to be embroidered can be hooped. See Dealing with items that cannot be hooped, see below.

Some items cannot be hooped, such as the edge of a napkin. Use the hoopless embroidery technique, then follow these instructions to embroider the cutwork.

To make the initial cut, lightly place a finger underneath the hooped material (being careful not to stretch the material) and use it to feel if the scissors has penetrated the stabilizer. I like to slide the point of the scissors into the material at an angle almost level to the fabric as this reduces the chance of piecing the stabilizer.

Here are some of the 24 designs from theVintage Cutwork (Set 1) Hatched in Africa design.

Beautiful cutwork designs can also be purchased from s-embroidery.com. They also have a cutwork tutorial and a free cutwork design to download and try.

Written by Elaine Raahauge - business writer and home embroiderer

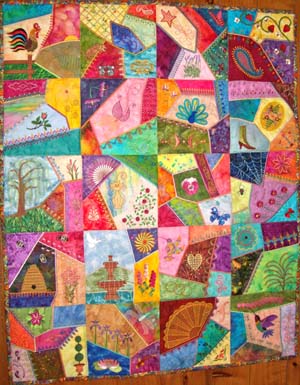

You can make appliqué blocks decorated with beautiful embroidery all in one step within your embroidery hoop. This tutorial uses a crazy quilt block to demonstrate how easy and fast it is to create a fun block that can be joined with others to make a crazy quilt.

This tutorial covers some of the basics of appliquéing in the hoop but each designer creates their designs differently so you cannot religiously follow the steps detailed here for all designs. I have written this tutorial to show you what is possible with your embroidery machine and to encourage you to create beautiful and fun things.

Follow these instructions to create this fun quilt block entirely in the embroidery hoop.

These blocks can be joined together to make a quilt or wall hanging.

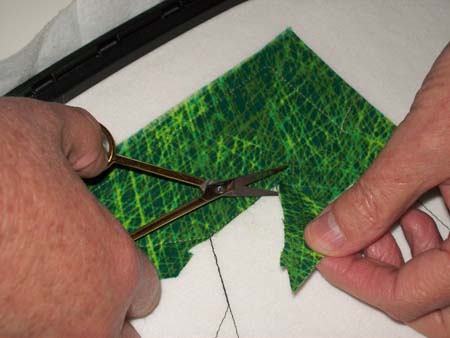

Appliqué in the hoop has many variations but it is basically where the embroidery machine appliqués pieces of material onto a background – usually a stabilizer. The machine stitches the outline of the block (including the placement lines for each piece of fabric) onto the hooped stabilizer. Individual pieces of material are laid over the outlines, stitched, then cut into the right shape. The machine joins the fabric together (usually with a satin stitch) then embellishes the block with embroidery. The result is an appliqué block that has been completed using only your embroidery machine.

There are five things you need to create an appliqué block similar to the crazy quilt block demonstrated here:

5. A small pair of scissors with a thin, sharp point. This is required for cutting away the excess material close to the sewing line and your curved embroidery scissors will not work here.

There are a lot of thread colours at the beginning of the block but it is not necessary for you to change the actual thread. They are called thread stops and are put there by the designer to stop the machine so you can place, or trim, the appliqué piece. Therefore, it is not necessary to change your thread each time there is a thread stop as this thread will not be seen. In the steps for embroidering the appliqué block (below), it is not necessary to change the thread colour until step 8.

Written by Elaine Raahauge – business writer and home embroiderer

Question: I have viewed your tutorial on Crazy Quilting. Can you please help me out as I make my quilts as "quilt as you go" so would I be able to use the embroidered designs for crazy quilts as a quilt block - ie top, wadding and backing in the all in one go? I am very interested in the design in the hoop crazy quilt, but it will not work if maybe the 'sandwich' was too thick? The designs in the hoop are so decorative that there would be little or no space to quilt in the traditional way - ie do the top and then layer. (Jenny N. from UK)

Suggestion: I embroidered my crazy quilt pattern directly onto a hooped cut-away stabilizer - laying down the fabric over the stabilizer, as required. Once all the blocks were completed, I removed the stabilizer from the seam line only then joined the blocks together with a quarter inch seam. I laid the quilt top over the backing and connected the two together by zig-zagging over the seam lines (from the front) I did not quilt the quilt as it doesn't need it and there is nowhere to quilt anyway.

I will try and explain why I did it this way and give you other options.

You can use anything as the base for the block. I chose the cut-away stabilizer because it is easy to hoop and it provides a solid foundation to build on. You could hoop a tear-away stabilizer and baste a layer of wadding (not too thick) over the stabilizer and lay the fabric directly onto the wadding. I have never hooped wading by itself and have no idea if this would work well. I would be worried about it stretching during the embroidering. Therefore, I recommend you use a stabilizer base with it. You can remove the tear-away stabilizer afterwards, if you want.

You can even use a layer of material as the base and then baste the wadding onto that. You may not even want to use wadding as it is really not required (as there is no quilting to enhance). If I was doing this again, I would hoop a layer of flannel and lay the applique fabric directly onto this. No matter what base material you use, the quilt will be stiff as there is so much decorative stitching on the blocks. If you use wadding, use the thinnest possible.

There is no way you would want to include the quilt backing in the layering in the hoop as you wouldn't want the back of the embroidery to be visible in the finished quilt. The backing has to be added after the embroidery is finished.

This is really a wall hanging rather than a quilt and is quite small. I have a large embroidery hoop and my blocks are 200mm x 200mm. If you don't have this sized hoop, you can make smaller blocks to fit your hoop. Therefore, you won't have a large and cumbersome quilt to fight with.

- Elaine Raahauge

Question: I am just starting out making gymnastics leotards in stretch lycra for my grand-daughter. I want to know what products are best to use to applique stretch cut-out designs onto stretch lycra. I figure I need a water-soluble "glue" sheet which will allow the fabric to be flexible when it is worn, and also a water soluble "stabilizer" for when I am sewing on the applique - is this correct? (from Magaret Neith - VIC)

_______________

Suggestion 1: You need to use applique wonder or visafix to the piece of fabric that is the cut-out. Make sure you have an applique mat when you are ironing the applique to the main garment. You must use a needle to suit stretch fabric and sew slowly. There won't be any stretch in the applique piece as the glue will become a little stiff. the needle is very important as the use of an incorrect one will result in small holes and ladders will appear. I hope this will help. (Helen Senior from Glenroy, VIC)

Suggestion 2: I have tried several techniques. The most successful (though time-consuming in the extreme) was to cut out the applique and spray it with embroidery spray on the back, place it on my fabric then lightly iron on (and pin) a tear-away stabilizer on the top, then zig-zag sew the edges through the stabilizer. This seemed to hold the lycra without any stretching. The most time-consuming bit was pickikng out the tear-away from between the stitches. I also tried the same technique but pinning a water-soluble fabric on the top of the applique instead then zig-zagging - this was OK, but did lead to a bit of "waviness" on the lycra. (Magaret Neith)

As rayon thread is made from a natural fibre, it must be stored correctly to protect it and to extend the life of the threads. The main problems areas are heat, light, moisture and dust.

There are several ways to store your threads and most are valid - with some provisions. The type of storage depends on the number and sizes of your threads and how often you need to access them. This article covers three ways to store threads that I have used successfully and one more I haven't tried. But there are doubtless many more ways and you may already used a better one.

It is important to secure the thread ends before you store the reels. You can tie a know but thread nets are much better and stop the thread from unravelling. I also use self-clinging tape (that sticks only to inself) but, under no circumstances, use sticky tape.

These are relatively cheap and can hold a good number of threads. They are handy because the cases are portable and you can move them around as you need to. You can put all your pinks/reds in one case and all your greens in another. On the down side, they can be too short for some reels and some don't provide the betst protection against light. This method works best when you have only a small number of threads as it can get pretty exprensive to keep buying more cases. The cases can have one or more compartments.

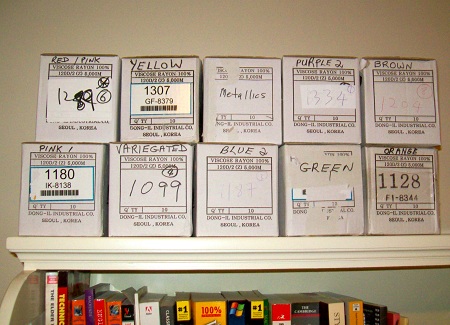

A good (and cheap) way is to store your Marathon thread is in the boxes they come in. You can write the colour name on the box to keep them organised and the threads always fit into the box. Plus, the boxes are free! On the downsides, you can't see your threads at a glance, e.g. when you have several boxes of greens.

Drawers are great for storage as they keep out the elements and the dust but can be expensive to purchase. This option suits embroiderers with a lot of the threads. The big advantage is that drawers hold a lot of threads so all my pinks and reds fit into one drawer and my blues in another - I just have to open one drawer to see all my threads in that colour group.

Furniture can take up to a lot of space so see if it can be incorporated with your sewing table. I use 'table legs' from Ikea that consists of five draweres - two drawers fit the 1000m reels and thread drawers suit the 5,000m reels and general embroidery notions. I use two of these table legs with a tabletop as the stand for my embroidery machine. They are really deep, so hold a lot of threads and essential notions. The drawers come in a flat pack and have to be assembled (always a pain unless you'r gifted in that area) but are easy to move around, if required, as the table legs are not attached to the tabletop. I have a third unit that I place to my right (as I'm right handed) where I place the threads that I'm using in my current project.

This image of the Vika Curry table leg is used with permission from Ikea. Ikea did not provide any assistance (financial or otherwise) for this article.

The drawer don't have to be new - look for second-hand desks and chest of drawers.

This is the option I have not tried and I don't know if Marathon thread reels fit. It does make the threads easy to see and access but leaves them exposed to heat, light and dust. If you have a thread rack on a wall or stand, keep it out of direct sunlight and cover it when not in use to keep out the dust.

Here are other great tips from Embroidery Library.

By Elaine Raahauge - Business writer and home embroiderer